What is LASER? | Our Laser Cutter

At JDM Plates, we use our own in-house laser cutter to craft the most pristine, accurately designed number plates bespoke to your order. We want to inform all our customers how we produce their number plates, and a ubiquitous part of our manufacturing process is by using our laser cutter.

What is a laser?

Colloquially spelt in lower case, a laser is, in fact, an acronym for Light Amplified by Stimulated Emission of Radiation (LASER). Therefore, LASER technology are all devices which emit one or more converged beam(s) of light through a process of optical amplification. Photons which are elementary particles that make up the electromagnetic (EM) spectrum and all EM wavelengths, act as the medium for what lasers are. Depending on the type of mechanical device used to produce them, lasers may have different properties and will be used for different applications.

Although we use lasers to cut out lettering for our number plates, they have several other uses ranging from optical disk drivers, printing, barcode/quick response (QR) code scanning, DNA sequencing, fibre-optics, photolithography, surgery, lighting and even in the military.

At JDM Plates, we have years of experience using laser cutting tools and have configured our in-house laser cutting device to specialise at cutting acrylic plastics and small shapes to the most precise degree of accuracy possible. This results in a far more high-quality finish.

How do laser cutters work?

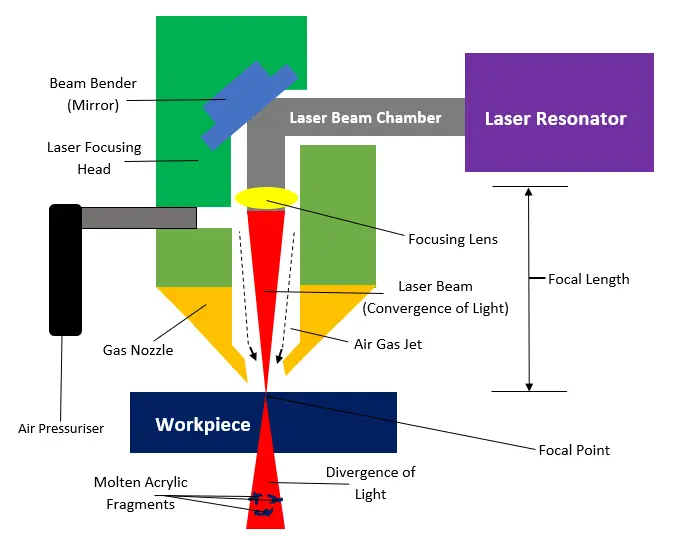

As previously mentioned, lasers involve the use of converging and amplifying photons onto a particular object which results in an extraordinary amount of energy and photons hitting its surface at once; causing it to instantaneously breakdown. The photons are what we fire from something known as a laser resonator, which are then excited in a laser beam chamber. This increases the photons activated energy until they reach a point where they will hit the end of the chamber, and bounce from a ‘beam bender’ mirror.

The mirror will refract the beam of photons at a 90° angel so that they will travel directly downwards. We will then use a laser focusing head to control the focusing lens which will in-turn cause the beam of photons to converge together so that they are even more concentrated together, where they will centre into what is called a focal point. The focal point is the smallest diameter of the photon beam, and it is what we aim onto the workpiece.

This process will naturally result in a lot of thermal energy contacting the workpiece itself, and will cause the workpiece to burn if such heat is not cooled down. To dissipate this thermal energy, we use an air pressuriser which sends a jet of pressurised gas collected from the air which will blow out from a gas nozzle surrounding the laser; removing heat with it. The pressurised air will also blow away molten acrylic fragments which break away from the workpiece as it is being cut, and if not removed right then could be exposed to the heat of the laser, which may cause it to liquify and remould to the workpiece again which will render it unusable.

It is at the focal point where the converged laser will then begin to diverge. This is because all the directions where the wavelengths of light converge together will continue to travel in the same direction, which means they will then travel away from each other. For a simpler, visual representation, imagine two sides of a square which leads to the same vertex (corner). If those two straight lines continued in the same direction they were going as they meet, they would then travel further away from each other exponentially.

This is what is happening to the photons in our laser beam, and the further apart they are from each other, the less effective the laser will be. It is only a very short distance before the laser’s divergence has made it completely ineffective. Below is a simple 2D diagram that illustrates how our laser cutter operates correctly.

Are They Worth It?

Using laser cutters are far more effective than practically any other cutting tool available and it is the only way to ensure your number plates are of the highest quality possible. Using physical tools such as industrial scissors, sawblades amongst other cutting equipment to cut out your plate numbers cause numerous problems. Firstly, these tools use different forces to cut out an object which would have an adverse impact on the workpiece which lasers do not.

For example, using industrial scissors utilises both compression and tension on a small surface area to pierce into an object which on a mechanical level, will cause large particles that make up the object to break apart from each other. Ultimately, this is not precise enough to cut out number plates based on the physical limitations/sizes the scissors need to be themselves so they do not break under the pressure they exert. Their use which is solely dependent on someone’s skills with using them, are therefore more likely to result in human error.

Even if we used a mechanical device which applied the same fundamental actions as scissors do to more accurately cut into the plastic, it would waste time and unnecessary plastic as it would need to cut through it until it reached the letter shape which had been traced onto the acrylic. The use of other physical (power) tools such as electric saws will produce friction which transfers thermal and kinetic (the vibrations from the power tool) energy which could weaken the overall durability of the acrylic plastic.

Moreover, using chemicals to cut out the lettering shapes may also cause reactions which release toxic fumes that will need to be ventilated out of the workspace, converted into non-toxic particles and/or trapped and stored in gas bottles depending on the fumes created by the chemicals, which can become very costly and inefficient in the making of the final product.

Using corrosive chemicals regardless of the reactions they have with the substance(s) they are reacted with, is a very hazardous process which requires constant monitoring from a qualified technician/specialist at all times. Such chemicals must also be stored correctly, and comply with all health and safety regulations. Alongside this, it is for all these reasons why we have opted to exclusively use a laser cutter for all our number plate characters. It is simply more effective, efficient and safer than any other cutting device.

Are They Safe?

We have taken every measure to ensure our laser cutter – and how it is appropriated – is safe for everyone within its vicinity. Although we are not able to verify every cutter out there, we use centrifugal exhaust fans as a part of our air filtration system to transport fumes produced from cutting the acrylic, out from our workspace. Air from the outside then circulates back into the building, meaning that the environment we work in is breathable, and safe.

Additionally, no one else besides our qualified engineers are permitted to use any of the laser equipment; all of which is self-contained in a room which is locked at all times except for when in-use and the room itself is decluttered to avoid any potential trip hazards.

Ordering Laser Cut Number Plates

We guarantee all our number plates are cut to legal sizes with precision, and have been produced in compliance with all health and safety regulations. We recommend you take look at our 4D number plates for all vehicles to preview our products. You can also use our Number Plate Builder to design your own number plate for yourself. Please visit out informative guide on 4D number plates For more information. We also laser cut all our hex plates.

For all our number plating enquiries, you can call us on 01493 230023. Alternatively, please feel free to get in touch via the contact forms across the website.